Applications of Ionic Liquids in Refining Processes

Petroleum refining has been one of the key technologies driving global economic development and technological advancement for well over a century. Although much of the technology used in refineries is considered mature, the industry is always seeking ways to make process improvements, reduce environmental impact, enhance safety, and achieve cost reductions. In particular, much focus has been placed on improving the existing technology for Hydrodesulfurization (HDS), Hydro-denitrogenation (HDN), Hydrodeoxygenation (HDO) and alkylation. Due to their unique physical and chemical properties and environmental advantages over traditionally used solvents or catalysts, interest in ionic liquids for such refinery processes has been increasing exponentially in recent years [1]. IL-based alkylation catalysts have been proven to facilitate efficient alkylation while avoiding the major challenges of corrosion (such as: Stress Corrosion Cracking), safety and operability issues associated with the traditional HF-based technology. Alkylation typically uses a catalyst such as sulfuric acid or HF to create high-octane gasoline. However, the use of HF has been associated with explosions at Philadelphia refinery. The US Chemical Safety Board (CSB) has called for safety regulations to be updated around the use of HF. Extractive desulfurization (EDS) of fuel oils using ionic liquids (ILs) has been intensively studied in recent decades and has a good future as an alternative or complementary method to HDS. This process is operated under harsh conditions, such as high temperature, high pressure, and requirement of a noble catalyst and hydrogen. By using this existing technology, the steel pipes may be prone to High Temperature Hydrogen Attack (HTHA) failure. HTHA (sometimes called ‘methane reaction’) occurs at high temperatures between the gaseous molecular hydrogen contained inside the steel pressure vessel and the carbon atoms located in the steel matrix or in carbides. Methane molecules are produced during this reaction. This phenomenon can consequently lead to a loss of mechanical properties due to surface decarburization and to the formation of defects caused by methane bubbles mainly located at grain boundaries. The Tesoro Anacortes accident occurred during startup of the refinery’s “naphtha hydrotreater unit” after a maintenance shut down.

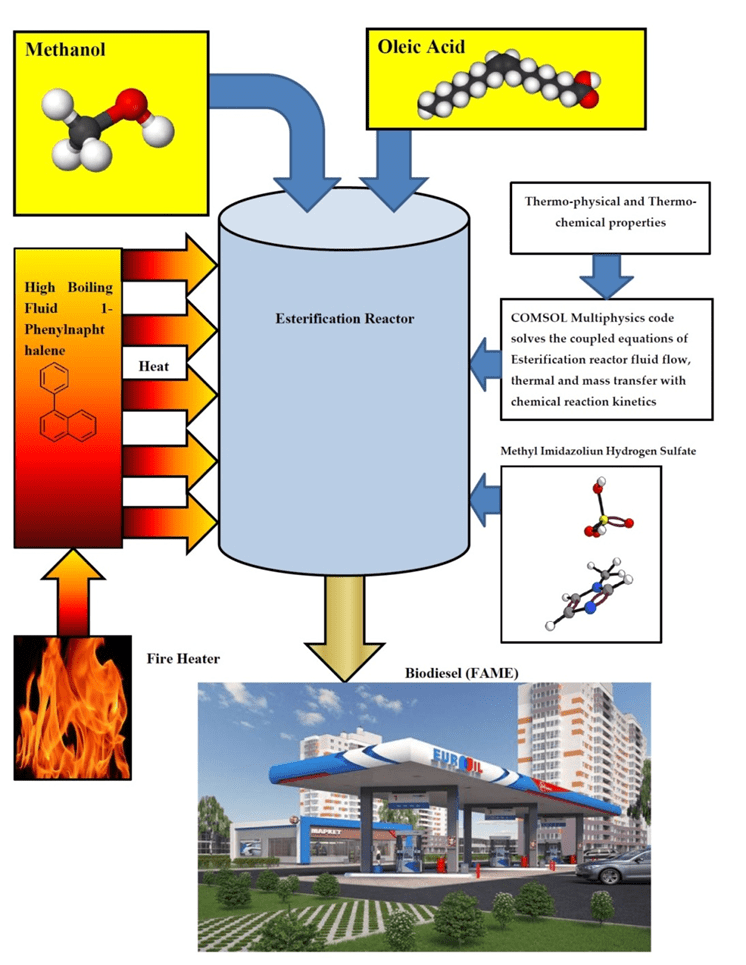

Robust simulation methodologies have been applied to analyze key IL applications: physical and chemical CO2 capture, gas separation, liquid–liquid extraction, extractive distillation, refrigeration cycles, and biorefinery [2].